Explosion proof equipment, winch, hoist & cranes

Explosion proof cranes & explosion proof hoists for hazardous dusty & gas workshops. 1- 75 ton single girder & double girder explosion proof overhead crane system for explosion proof & flame proof workshops with high safety and efficiency.

| Crane Type | Explosion proof crane,hoist, winch |

| Crane Capacity | 0.25 ton to 100 ton |

| Crane Span | Customized |

| Lifting Height | Customized |

Category: Overhead Crane

Your Trusted Overhead Crane Manufacturer & Supplier

Explosion Proof Hoist and Crane & Winch

Exproof Hoisting Equipment for Hazardous Hoisting Applications

Explosion proof cranes and explosion proof & flame proof hoists, and explosion proof winches for hazardous dusty & gas application such as oil rigs, gas liquefaction plants , mines or chemical industry and other various hazardous applications wherever explosive gases or dusts predominate may have the potential of existing.As an explosion proof hoist and crane manufacturer, we are well experienced for anti-explosion crane and related equipment fabrication and installation. Explosion-proof crane equipment, feature sturdy construction, high functionality and extremely long service life.

Explosion proof crane

Explosion proof overhead crane is a type of particularly designed overhead travelling cranes, mainly used to handle materials in workshop, warehouse and factory with hazardous explosive gas or dust with high safety and reliability. The explosion proof crane is equipped with explosion proof measures to ensure highest level of safety in motors, electrical crane parts, metal contact surface and even crane wheels to avoid flame by friction, conforming to national and international standards, which is a good selection for hazardous application environments such as oil refineries, gas power plants, petrochemical, paint processing plant, etc.

Safe & reliable anti-explosion proof hoist and cranes of various overhead travelling crane designs and wide crane specifications are available. 1 ton -20 ton single girder explosion proof crane & 5 ton -75 ton double girder crane explosion proof crane designs are available. Custom designed explosion proof crane system with explosion proof & flame proof hoists for your workshops with high safety and efficiency even under most demanding conditions.

Single girder & double girder explosion proof cranes

The explosion proof crane can be grouped into difference categories based on different standards. Generally, it can be grouped in the the following types:

Explosion proof crane systems are available with various overhead travelling crane designs including single girder overhead cranes, double girder overhead cranes, top running overhead cranes & under hung overhead cranes, equipped with explosion proof hoists for hazardous applications, and anti-explosion and spark resistant crane parts and components for hazardous industrial applications such as oil rigs, gas liquefaction plants , mines or chemical industry and other various hazardous applications wherever explosive gases or dusts predominate may have the potential of existing.

On crane girder designs, the number of crane girders, the explosion proof crane can be grouped as follow:

- Single girder explosion proof crane; is a single girder overhead travelling crane, designed for load handling with capacity up to 20 ton.

- Double girder explosion proof crane: is a double girder overhead travelling crane, designed for heavy duty material handling with capacity up to 75 ton.

As the most frequently mentioned types, the single girder explosion proof crane and double girder explosion proof crane will be presented in length for your reference to get your best value overhead travelling cranes for your application.

The single girder type and double girder type explosion proof cranes are designed and processed based on Ex d (flameproof enclosure) and Ex e (increased safety) with CE marking: II 2G ck Ex de IIB T4 (standard), II 2G ck Ex de IIC T4 (Special), II 2D ck Td A21 IP66 T135 (DUST).

LB series of single girder explosion proof cranes

LB single girder explosion proof cranes is light duty cranes, designed with the structure of common single girder overhead cranes but equipped explosion proof hoists as the lifting system. All the motors and electrical equipment is explosion proof and even the crane wheel is in accordance with the standard of JB/T10219-2000, which is made of stainless steel or nylon to ensure safety during operation to avoid friction sparks.. The explosion proof grades of the overhead cranes are ExdⅡBT4 and ExdⅡCT4.

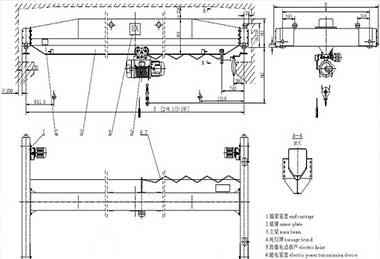

Single girder overhead explosion-proof crane is mainly consisted of bridge crane traveling mechanism, electrical system with anti-explosion electric parts and components, bridge girder, explosion-proof hoist and other crane parts and components.

Explosion proof crane with single girder crane design

Explosion proof crane with single girder crane design drawing

Main parameters of single girder explosion proof crane

The lifting capacity of single girder overhead explosion-proof crane is 1-20 tons and crane working class are A3 or A4. The specific crane parameters are presented for your reference.Customized explosion proof crane is available by leaving a message below.

LB Single girder explosion proof crane parameters:

- ·Lifting capacity of single girder explosion proof crane : 1~20t

- ·Span length of single girder explosion proof crane: 7.5~28.5m

- ·Lifting height of single girder explosion proof crane: 6~18m

- ·Lifting speed of single girder explosion proof crane: 3~8m/min or 3/0.3~8/0.8m/min

- ·Crane travelling speed of single girder explosion proof crane: 20m/min

- ·Explosion proof grade: ExdⅡBT4、ExdⅡCT4

- ·Working Class: A3

QB series double girder explosion proof overheadcrane

QB series of explosion proof crane is a double girder overhead crane designed for workshops or factories with flammable gas or explosive gas mixture of which detonating ability is not higher than IIB or IIC. The double girder crane is designed for heavy duty martial handling and all the motors and electrical components of the overhead crane conforms to the standard of GB3836.2-2000 with features of anti -explosion and the whole crane system is designed in compliance with the crane standard of JB/T5897-2006. The explosion proof grades of the double girder explosion proof cranes are ExdⅡBT4 and ExdⅡCT4.

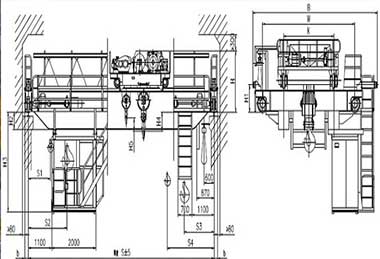

Explosion proof crane with double girder crane design

Explosion proof crane with double girder crane design drawing

The main parts and components of the QB series double girder explosion proof crane includes the crane bridge structure, trolley winch lifting mechanism, crane traveling mechanism, explosion proof electrical equipment and so on. The drawing of the double girder explosion proof crane is presented for your reference.

Optionally, specialized features can be added by equipping custom designed devices, such as rain proof device when the explosion proof crane is applied in the open air. Leave your requirements below to get your individualized explosion proof double girder overhead travelling cranes.

Main specifications of double girder explosion proof cranes

The lifting capacity of the explosion-proof double girder overhead crane is 5-75 tons, and crane working class is A4 and A5.The specific parameters of the explosion proof cranes are presented for your reference. The customized double girder explosion proof crane is available.、

Main specifications of double girder explosion proof cranes:

- Lifting capacity of double girder explosion proof crane: 5~75t

- Span length of double girder explosion proof crane: 10.5~31.5m

- Lifting height of double girder explosion proof crane: 6~18m

- Lifting speed of double girder explosion proof crane: 3~5m/min

- Crane travelling speed of double girder explosion proof crane: 20m/min

- Explosion proof grade: ExdⅡBT4、ExdⅡCT4

- Working class: A4

Being proven under the demanding application environment, the explosion proof cranes and explosion protected hoists are trusted with popularity.

With rich experience and flexible designs, our explosion proof crane systems is winning partners around world for the quality of the supplied overhead lifting equipment, personalized crane design, and on time delivery to meet the manufacturing plan of valuable clients at competitive prices.

Any need of explosion proof crane and hoist systems, please feel free to contact us.

Parts & components of explosion proof overhead travelling cranes

Explosion proof crane is a type of particularly designed overhead travelling cranes, mainly used to handle materials in workshop, warehouse and factory with hazardous explosive gas or dust with high safety and reliability. The explosion proof crane is equipped with explosion proof measures to ensure highest level of safety in motors, electrical crane parts, metal contact surface and even crane wheels to avoid flame by friction, conforming to national and international standards, which is a good selection for hazardous application environments such as oil refineries, gas power plants, petrochemical, paint processing plant, etc.

Main girder of explosion proof crane are fabricated with quality steels and covered with specified paints including 3 layers1) Dimer coat 9 primer( 75 microns drt),2) Amercoat 385 ( 150 microns drf),3)Amercoat 450S( RAI 1004 OR 1018) (75 microns drt), etc. Tailored explosion proof hoists & cranes are available.

First layer of the special paint for the explosion proof crane

Second layer of the special paint for the explosion proof crane

Third layer of the special paint for the explosion proof crane

Crane travel stainless wheel for the explosion proof crane

Hoist travel stainless wheel for the explosion proof crane

Explosion proof hoists for the explosion proof crane

Hoist explosion-proof electric box for the explosion proof crane

Crane explosion-proof electric box for the explosion proof crane

Explosion proof control for the explosion proof crane

The explosion proof hoists and cranes offers a wide range of lifting height or hook height and lifting speeds incorporating with the standards of FEM, ISO, AS, ATEX, and IECEX, with the features of reliability, durability and easy maintenance. All components of the explosion proof hoists are carefully designed to suit the particularly targeted hazardous zones to make the explosion proof crane hoists manufactured to suit the specifications of application to further improve the reliability, safety and performance.

According to the crane application, the explosion proof cranes can be sorted into :

- Mining explosion proof crane: mainly used on the coal mine under the mine of non-mining surface and a MA certificate is a " must-have".

- Factory explosion proof crane: mainly used in workshops of factories with dangerous flammable gas or dust or other types of mixture and the explosion-proof certification issued by National Testing Center is required.

All of our explosion proof hoists , winches and cranes are designed and processed based on Ex d (flameproof enclosure) and Ex e (increased safety) with CE marking: II 2G ck Ex de IIB T4 (standard), II 2G ck Ex de IIC T4 (Special), II 2D ck Td A21 IP66 T135 (DUST).

Explosion proof hoists & winch

Explosion Proof Hoists and Cranes series is designed and manufactured by the state-of-the-art CNC machine tools set up particulerly for production of hoists and winches. The modular design explosion proof hoists and cranes enables specific materials selection for hazardous and corrosive environment requirements.

Explosion proof electric chain hoist

Electric chain hoists mounted on hook, lug, manual or electric hoist trolley for types of electric chain hoist cranes with capacity of 500kg, 5 ton, 10 ton, 32 ton.

Explosion proof wire rope hoist

Wire rope hoists with explosion proof, flame proof & spark resistant hoist designs to secure your electric hoist crane. Check wire rope explosion proof hoists now.

Explosion proof manual hoist

Explosion-proof manual hoists are widely adopted in the hazard environments with the potential danger of fire and explosion, such as, petroleum, petrochemical, gas station, oil depot and gas extraction, chemical industry, electric power, mining, electronics, railway, etc.

Explosion proof air hoist

Air hoist & pneumatic hoist is a compressed air powered hoist & air operated hoists, various hoist designs, explosion proof, shock proof, wide specification.

Explosion proof pulling & hoisting winch

Mining winch & types of mining winch systems for gold, copper,silver, iron, zinc & coal mine.Underground mining winch & explosion proof winch for sale.

Explosion proof air winch

Air winch & pneumatic winch is an air powered winch or air operated winch for pulling & hoisting loads of 500kg to 10 ton, explosion proof pneumatic winch

The explosion proof hoists and cranes offers a wide range of lifting height or hook height and lifting speeds incorporating with the standards of FEM, ISO, AS, ATEX, and IECEX, with the features of reliability, durability and easy maintenance. All components of the explosion proof hoists are carefully designed to suit the particularly targeted hazardous zones to make the explosion proof crane hoists manufactured to suit the specifications of application to further improve the reliability, safety and performance.

Advantages of Explosion Proof Crane and Hoists

Based on international advanced crane standards, the explosion proof overhead crane is designed and processed with the advantages of reasonable crane structure, high performance with high safety and reliability , travelling crane operation with high flexibility and stability and strong explosion-proof performance.

- Simplified crane structure is mainly composed of box type main crane girder, end beam/ end carriages, explosion proof hoist trolley and electrical system, etc.

- High safety and reliability is guaranteed for the trolley conductive system by adopting the I-beam rail conductive device。

- High versatility and standardization is realized in terms of parts of overhead travelling cranes.

- Crane operation is performed with high flexibility and safety which is conducted and completed in the crane operator's cab with a wide vision .

- Explosion protection: II 2G ck Ex de IIC T4 and II 2D ck Td A21 IP66 T135 (DUST)

- Enclosure can be up to IP66 for protection against flammable dust or extreme conditions

As a licensed overhead traveling crane manufacturer with explosion-proof certificates, the explosion proof cranes and hoists manufactured is guaranteed in quality and performance in strict compliance with the national designing standards of explosion proof cranes and hoists.

Explosion proof protection

How to avoid explosion ? To avoid the creation of an explosive environment or atmosphere is naturally the first option and the most easiest way with high safety. For example, to provide the adequate and effective ventilation or confine the work processes to prevent the appearance of dangerous gases or dusts in the closed system.

Secondly, to prevent the explosive atmosphere from ignition is also an effective to prevent explosion . To justify this aim, the surface temperature of the explosion proof equipment must be limited and the creation of sparks or sources of ignition must be avoided.

Lastly, the effects of an explosion must be controlled and reduced to a negligible level. Usually, it is conducted by isolating the ignition source, e.g. by mounting explosion proof equipment in flameproof enclosures, etc.

Explosion proof hoist and crane use the explosion protection of removal of potential sources of ignition to prevent explosion by adopting specialized hoist parts & components and together with ongoing monitoring of potentially hazardous environments. What's more, the explosion proof hoist and crane are also used in explosion proof and flame proof workshops.

Explosion proof crane systems are available with various overhead crane designs including single girder overhead cranes, double girder overhead cranes, top running overhead cranes & under hung overhead cranes, equipped with explosion proof hoists for hazardous applications, and anti-explosion and spark resistant crane parts and components for hazardous industrial applications such as oil rigs, gas liquefaction plants , mines or chemical industry and other various hazardous applications wherever explosive gases or dusts predominate may have the potential of existing.

Safe & reliable anti-explosion proof hoist and cranes of various overhead crane designs and wide crane specifications are available. 1 ton -20 ton single girder explosion proof crane & 5 ton -75 ton double girder crane explosion proof crane designs are available. Custom designed explosion proof crane system with explosion proof & flame proof hoists for your workshops with high safety and efficiency even under most demanding conditions.

Note on explosion proof overhead crane zoning

Hazardous areas are categorized into zones according to the assessment of the frequency of the occurrence and duration of an explosive atmosphere. A zone is an area in which an explosive gas atmosphere:

- is present continuously or for long periods of time, Zone 0;

- is likely to occur in normal operation, Zone 1;

- is not likely to occur in normal operation and, if it occurs, will only exist for a short time. Zone 2.

- Explosion Proof overhead crane Zoning: Zone 1 & Zone 2 Hazardous Areas

Applications of explosion proof cranes and hoists

A wide range of hazardous area hoist and crane equipment is designed and manufactured in our factory, including explosion overhead, gantry and jib cranes and all related components including explosion proof wire rope hoists and chain hoists, traveling system, end carriages and crane controls, etc.

- The explosion-proof grade of the single girder overhead crane is EXD II BT4 and EXD II CT4 respectively.

- The overhead crane is widely used in internal factories with low initiation capacity of IIB and IIC, and flammable mixed environment of T1-T4 ignition temperature class.

- The explosion-proof eot crane Zoning: Zone 1 & Zone 2 Hazardous Area.

- We designs and manufactures the explosion proof and anti -explosion proof hoist and crane equipment for the harsh and hazardous application environments, such as, chemical plants, gas power plants, paint shops, mining, oil refineries, and waste water treatment plants, etc.

As crane manufacture and supplier with profound foundation and experience, we can offer you a reliable anti-explosion crane and hoists which can be widely used in dangerous workshops or factories such as, chemical or petrochemical plants, oil refineries, gas power plants, waste water treatment plants, and paint shops, offering highest leave of safety. Leave us your email now in the below table to get our professional consultation on the explosion proof hoist and crane and get free Hoist and Crane pdf brochure.

Main Projects

Related Products

6.3 ton overhead crane kit for sale Philippines, complete single girder top running overhead crane system, low headroom design for workshop indoor use.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch